PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is specialized in bearings export production selling and after-service. In practice for many years, we established strict quality assurance system. Our products range covers motor cover and lamination,ball bearing,carbon brush,insulation paper,fan,thermal protector,magnet,etc.We can do OEM products, and do following drawings.

Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing. Make motor, turn to Nide, everything will be easy !

| Parameter | Information |

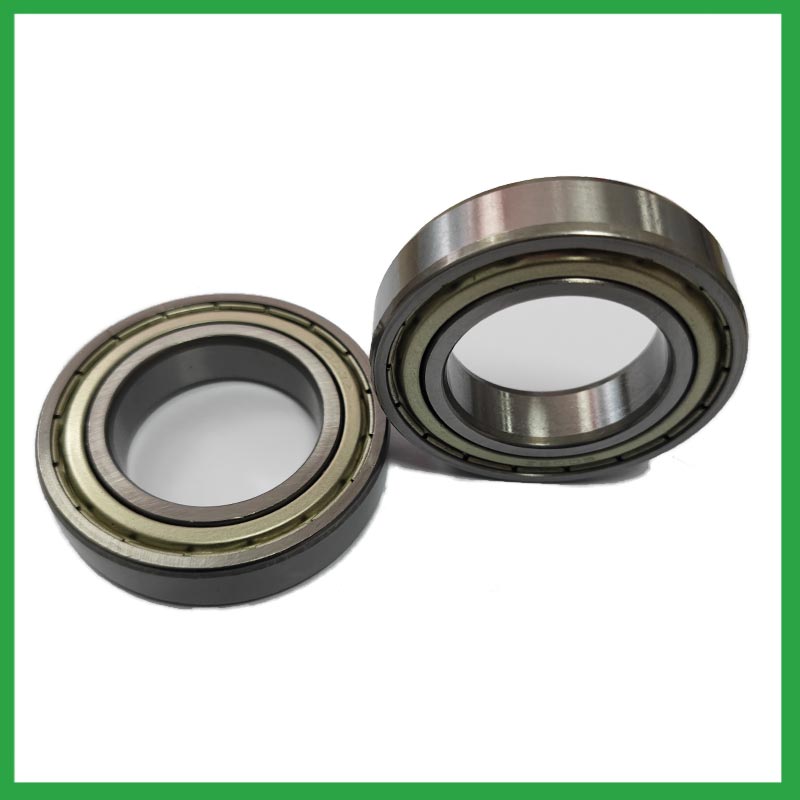

| Product Name | ball bearing 1 inch bore |

| Brand Name | Nide |

| Place of Origin | Ningbo,China |

| Type | Ball |

| Material | chrome steel, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | fan electric motor, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Samoa,Mauritius,Russia,British Virgin Islands,Brunei...etc |

| Export region | Europe,Oceania,Asia... |

| Certification | ISO 9001 Certification,CE-stator coil lacing machine,CE-stator coil winding machine,etc |

| Precision Rating | as per customer's requirement |

| Feature | High precision,High speed...etc |

| Packaging Details | Suitable for sea transportation |

| Color | Silver gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of ball bearing 1 inch bore is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing 1 inch bore---FAQs Guide

2.Are there miniature ball bearing 1 inch bore designed for use in precision instruments and small-scale mechanisms?

3.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

4.About ball bearing 1 inch bore,What about the lead time?

5.What are the standard sizes and dimensions of ball bearing 1 inch bore?

6.Are there hybrid ball bearing 1 inch bore that combine steel rings with ceramic balls to optimize performance in demanding applications?

7.As a ball bearing 1 inch bore manufacturer,What is your payment method?

8.What are the ball bearing 1 inch bore product skill training options?

9.What are the after-sales services available for ball bearing 1 inch bore?

10.What anti-corrosion coatings or treatments are available for ball bearing 1 inch bore used in marine or outdoor applications?

11.Can ball bearing 1 inch bore be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

12.As a ball bearing 1 inch bore manufacturer,How Can We Guarantee Quality?

13.What are the common materials used in ball bearing 1 inch bore manufacturing?

14.About ball bearing 1 inch bore,Will you check the products before shipment?

1.How do ball bearing 1 inch bore contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

2.Are there miniature ball bearing 1 inch bore designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

3.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a ball bearing 1 inch bore manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

4.About ball bearing 1 inch bore,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

5.What are the standard sizes and dimensions of ball bearing 1 inch bore?

ball bearing 1 inch bore size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

6.Are there hybrid ball bearing 1 inch bore that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic ball bearing 1 inch bore. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

7.As a ball bearing 1 inch bore manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

8.What are the ball bearing 1 inch bore product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

9.What are the after-sales services available for ball bearing 1 inch bore?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

10.What anti-corrosion coatings or treatments are available for ball bearing 1 inch bore used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether ball bearing 1 inch bore are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

11.Can ball bearing 1 inch bore be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, ball bearing 1 inch bore can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

12.As a ball bearing 1 inch bore manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

13.What are the common materials used in ball bearing 1 inch bore manufacturing?

Most ball bearing 1 inch bore are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

14.About ball bearing 1 inch bore,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.