PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is a professional manufacturer engaged in bearing research and sales. The factory covers an area of over 9000 square meters and has over 100 employees. The company has modern production equipment and advanced testing instruments. We produce deep groove ball bearings, spherical roller bearings, fan,carbon brush,shaft,ball bearing,commutator,motor cover and lamination, etc. The bearing accuracy is P0, P6, P5, P4 levels, widely used in fan motor,electric bicycle motor,BLDC motor,water pump motor,servo motor,electric automotive motor,washing machine motor,air condition motor. Passed ISO9001:2015 and CE status.

We adopt first-class production equipment and a comprehensive testing system, and hire excellent technical personnel for operation and management. Our bearings are now very popular in the United States, Canada, Türkiye, Russia, Argentina Micronesia, Federated States of,Gambia,Rwanda and other countries and regions.Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing.

| Parameter | Information |

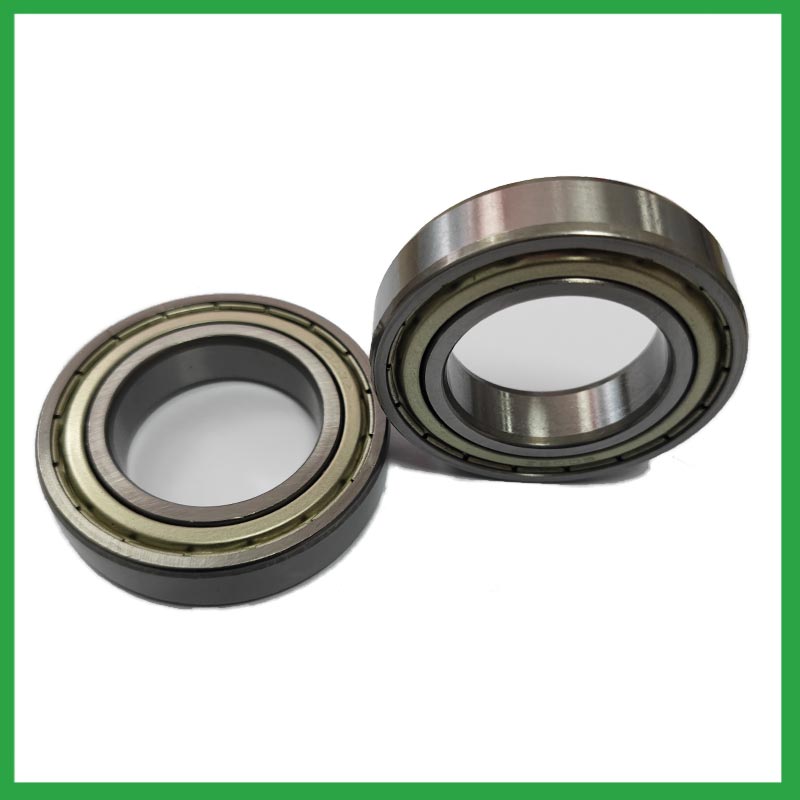

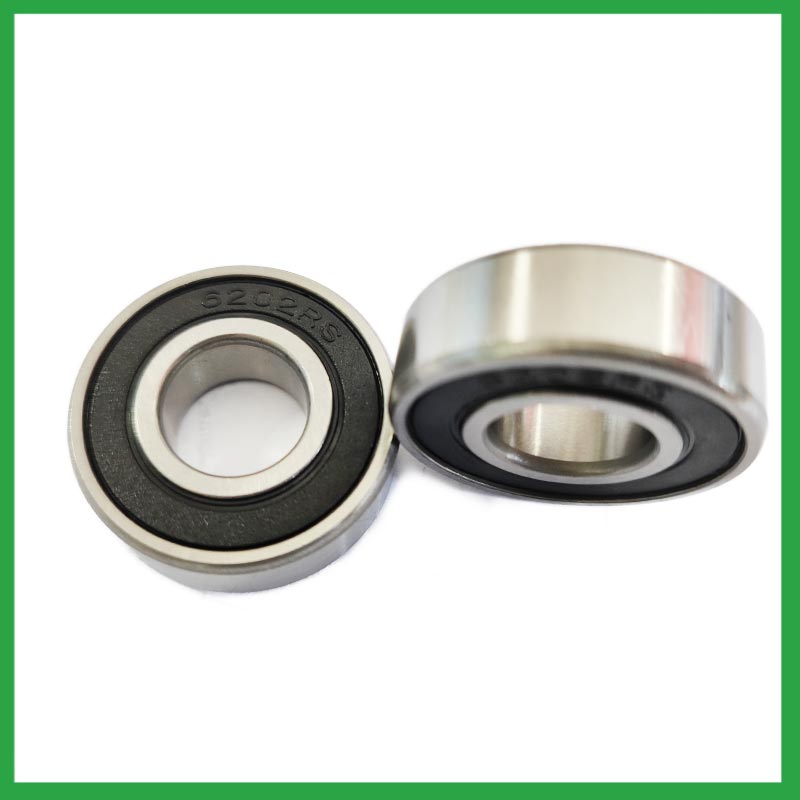

| Product Name | ball bearing door hinge |

| Place of Origin | China |

| Brand Name | Nide |

| Material | ceramics, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | automotive engines,machine tools, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil forming machine,CE-stator coil lacing machine,etc |

| Feature | High speed,Good wear resistance...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

ball bearing door hinge can be used in household appliances, such as mixers,refrigerator door leaf wings,barrel machine spindle bearings,washing machines, etc; It can also be used in industrial fields, such as bearing cabinets,weighing machines,reducers,weaving machine spindle bearings, etc.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing door hinge---FAQs Guide

2.What is the role of ball bearing door hinge in reducing friction and energy loss in rotating machinery?

3.Are there ball bearing door hinge designed for extreme temperature environments, such as cryogenic or furnace applications?

4.How do ball bearing door hinge provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

5.How do different ball bearing door hinge designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

6.As a ball bearing door hinge manufacturer,Your product certifications?

7.How do manufacturers ensure the quality and reliability of ball bearing door hinge through material selection and precision machining?

8.What are the advancements and innovations in ball bearing door hinge technology that have emerged in recent years?

9.Can ball bearing door hinge be used in both vertical and horizontal orientations?

10.Where can ball bearing door hinge be used?

11.How do sealed ball bearing door hinge prevent the ingress of contaminants and extend the bearing's service life?

12.How do cage designs affect ball bearing door hinge speed and acceleration capabilities in high-speed machinery?

13.What are the considerations for choosing between open, shielded, or sealed ball bearing door hinge in specific applications?

1.About ball bearing door hinge,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

2.What is the role of ball bearing door hinge in reducing friction and energy loss in rotating machinery?

ball bearing door hinge reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

3.Are there ball bearing door hinge designed for extreme temperature environments, such as cryogenic or furnace applications?

High temperature ball bearing door hinge use specialized lubricants to stand up to high temperatures. Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

4.How do ball bearing door hinge provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearing door hinge operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

5.How do different ball bearing door hinge designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearing door hinge: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

6.As a ball bearing door hinge manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

7.How do manufacturers ensure the quality and reliability of ball bearing door hinge through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

8.What are the advancements and innovations in ball bearing door hinge technology that have emerged in recent years?

Significant advancements have been made in ball bearing door hinge steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

9.Can ball bearing door hinge be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations.

Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

10.Where can ball bearing door hinge be used?

ball bearing door hinge are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

11.How do sealed ball bearing door hinge prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the ball bearing door hinge. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

12.How do cage designs affect ball bearing door hinge speed and acceleration capabilities in high-speed machinery?

In high-speed ball bearing door hinge, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

13.What are the considerations for choosing between open, shielded, or sealed ball bearing door hinge in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded ball bearing door hinge can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.